What are Temperature Probes?

How Temperature Probes Work: A Simple Overview

Temperature probes play an indispensable role across various industries, subtly tucked into processes where precision and accuracy in measuring heat are non-negotiable.

These sophisticated instruments range from simple thermocouples to complex resistance temperature detectors, each designed to offer reliable readings essential for quality control and safety.

Whether it is monitoring the delicate environment of a laboratory incubator or ensuring the optimal ingredients simmer in a culinary pursuit, temperature probes offer an unblinking eye over thermal conditions.

Discovering the underlying principles that make these devices so effective unveils a fascinating intersection of physics and engineering.

Keep reading to unwrap the layers of technology behind temperature probes and their critical applications.

Understanding the Basics of Temperature Probes

At the heart of temperature monitoring systems lie temperature probes, playing an instrumental role in many industries.

These precision instruments vary widely, each tailored for a specific function, setting, or temperature range.

This section will shed light on the diverse spectrum of temperature sensors, each uniquely designed to capture and relay thermal data accurately.

Additionally, readers will gain insight into the essential components of a temperature probe, dissecting the sophisticated engineering that empowers countless sectors to meticulously monitor thermal environments.

Exploring the Different Types of Temperature Sensors

Navigating through the array of temperature sensors, one encounters innovations designed for precision across diverse applications: from the robust thermocouple, ideal for high temperatures in industrial settings, to the sensitive thermistor, favored in laboratories for its accuracy in limited temperature ranges.

- Thermocouples: best for high temperature and rugged environments

- Resistance Temperature Detectors (RTDs): known for their precision and stability

- Thermistors: valued for their sensitivity within a narrower temperature scope

- Infrared Sensors: used for non-contact temperature assessment, critical in certain manufacturing processes

- Semiconductor Sensors: offer digital temperature reading, making them a choice for consumer electronics

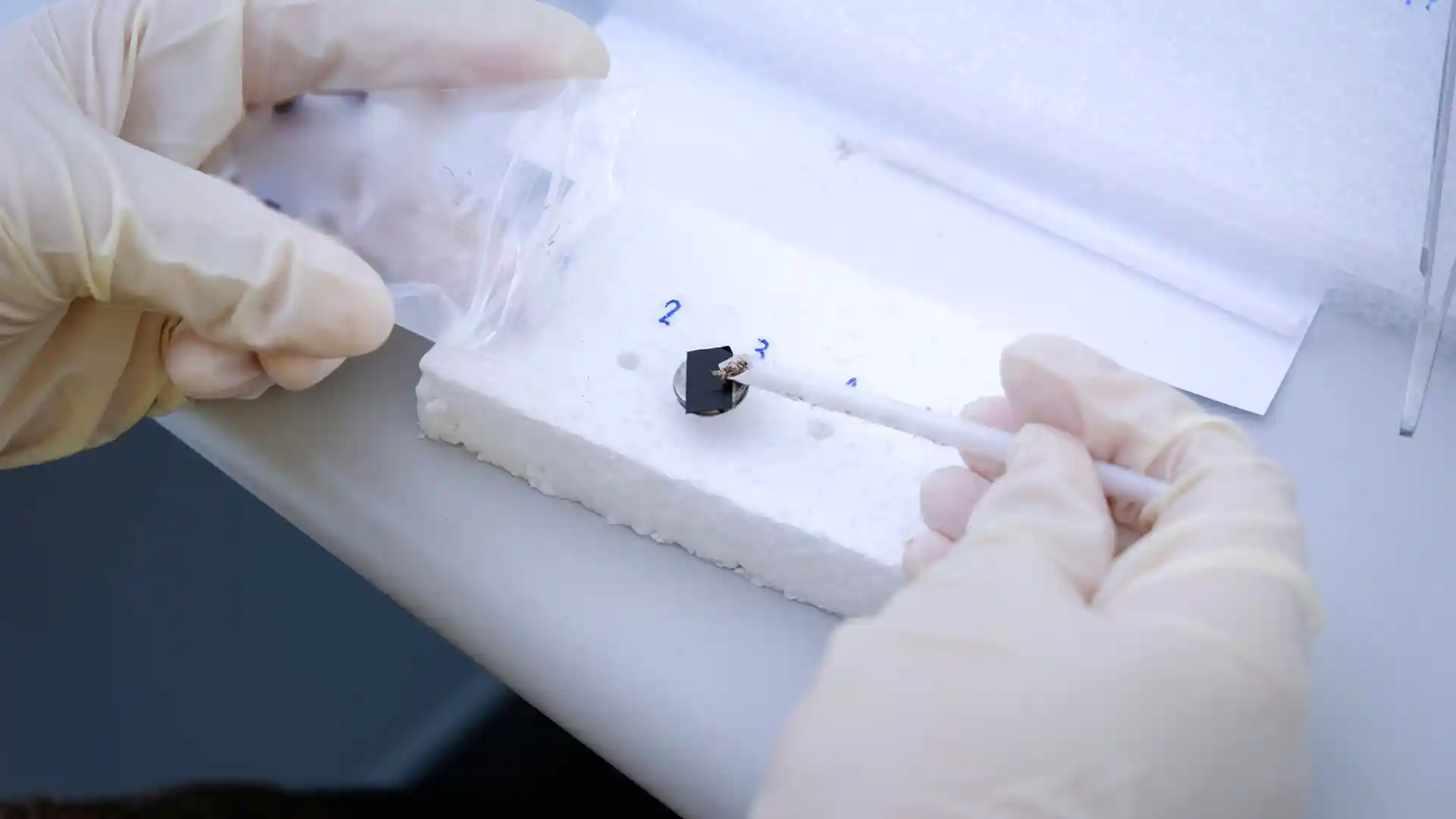

Unveiling the Core Components of a Probe

Temperature probes consist of several key elements that work in concert to detect and measure heat levels. The sensing element, typically a resistor, thermocouple, or thermistor, responds to temperature changes. Enclosed within a protective sheath, these components connect to a transducer that translates thermal data into readable signals for temperature monitoring systems or a temperature data logger.

The Inner Workings of Thermocouple Probes

Embarking on an exploration of thermocouple probes offers a fascinating glimpse into the practical application of the thermoelectric effect, which is the cornerstone of their function.

These devices harness the physics of metal junctions, where the merger of dissimilar metals creates a unique voltage when subjected to temperature variations.

This essential interaction furnishes the basis for precise temperature gauging across various environments.

By perceiving subtle shifts in voltage corresponding to thermal changes, thermocouple probes are indispensable in realms where accurate temperature data is pivotal.

How Thermoelectric Effects Enable Temperature Measurement

The thermoelectric effect is the fundamental principle that empowers thermocouples to measure temperature. When two dissimilar metals are joined at one end and exposed to heat, they generate a voltage that can be measured and correlated with temperature.

- The thermoelectric effect, also known as the Seebeck effect, describes how a circuit made of two different metals produces a voltage when the junctions are at different temperatures.

- Thermocouples employ this effect by measuring the generated voltage, which increases linearly with temperature, allowing for accurate thermal readings across various industrial applications.

- Technicians leverage sophisticated equipment to interpret these voltage fluctuations as temperature readings, translating the physical properties into actionable data with high levels of precision.

Decoding the Voltage-Temperature Relationship

The marriage of voltage and temperature within a thermocouple is an elegant expression of physics in action. As the junction of dissimilar metals experiences temperature fluctuations, the resulting voltage change offers a reliable gauge of the thermal state. Precise calibration ensures the translation of voltage differentials into accurate temperature readings, enabling meticulous control and monitoring across various industries.

Resistance Temperature Detectors Explained

Peering into the technical tapestry of temperature surveillance, Resistance Temperature Detectors, commonly known as RTDs, emerge as quintessential instruments renowned for their heightened accuracy and stability.

These detectors operate on the principle that a metal’s electrical resistance fluctuates predictably with temperature changes.

Throughout industrial and commercial domains, RTDs are revered for their ability to provide consistent and calibrated readings, making them an invaluable tool for stringent temperature control.

The forthcoming discussion will elucidate the operational mechanics behind RTDs, shedding light on the selection of materials and design choices that contribute to their remarkable performance in heat measurement applications.

The Role of Metal Resistivity in Measuring Heat

In the domain of precision temperature assessment, Resistance Temperature Detectors harness the predictable change in a metal’s resistivity due to temperature alterations to deliver accurate readings. The resistivity, intrinsic to metals like platinum, increases linearly with temperature, providing a reliable metric for temperature probes to quantify the degree of heat with a high degree of accuracy.

Detailing RTD Sensing Mechanism and Materials

At the core of a Resistance Temperature Detector’s sensing mechanism lies its meticulous use of metals with predictable resistivity variations when subjected to temperature fluctuations: platinum is the gold standard, celebrated for its almost perfect linear response to thermal changes. This proficiency stems from a delicate balance of material properties, where design intricacies converge to provide unrivaled sensitivity and accuracy. These detectors, exceptionally responsive to the dynamics of thermal environments, serve as the backbone of reliable temperature monitoring in various applications.

- RTDs utilize metals like platinum which exhibit a consistent, predictable increase in electrical resistance with rising temperatures.

- The exacting selection of materials and refined construction results in probes that can operate with a high level of precision.

- Engineers and scientists favor RTDs for applications wherein long-term stability and repeatability of temperature readings are paramount.

Discovering How Infrared Probes Detect Heat

In the quest to understand temperature dynamics from a distance, infrared probes provide an elegant solution.

These sophisticated devices leverage the scientific principles of radiation to capture thermal information without direct contact.

In sectors ranging from manufacturing to healthcare, the inherent characteristics of infrared probes afford significant advantages by enabling the swift, non-intrusive recording of temperature data.

This segment illuminates the scientific underpinnings of remote temperature sensing and explores the distinctive benefits of using infrared technology to gauge heat accurately and efficiently.

The Science Behind Remote Temperature Sensing

Infrared probes utilize the science of thermography, a branch of physics concerned with thermal radiation and its correlation to surface temperature. Objects emit infrared energy which varies with temperature; these probes detect and measure this energy without touching the object, rendering a visual representation of thermal variance across its surface. Such non-contact methodology not only preserves the object’s integrity but also allows for rapid assessments across hazardous or inaccessible areas.

- Thermography translates infrared radiation into temperature readings.

- Non-contact measurement prevents object contamination and enables quick analysis.

- Infrared probes are particularly useful in environments where traditional probes are unsuitable.

Advantages of Non-Contact Measurement With IR Probes

Infrared probes revolutionize temperature assessment by providing accurate readings without necessitating physical contact: a significant boon for applications where traditional probes may compromise the subject’s condition or where the environment poses a danger to the operator.

- By avoiding direct contact, infrared probes eliminate the risk of contamination and maintain the integrity of sensitive materials or sterile conditions.

- Their rapid response time accelerates the data collection process, thus enhancing efficiency in dynamic environments where conditions can change swiftly.

- Infrared technology extends temperature data collection to harsh or hazardous surroundings, protecting the safety of personnel while still securing crucial thermal information.

Navigating Through Thermistor Functionality

Nestled within the realm of temperature sensing technologies, thermistors distinguish themselves with their exceptional sensitivity and rapid response to temperature fluctuations.

Consisting of semiconductor materials that exhibit a stark change in resistance with slight variations in temperature, thermistors provide unmatched precision in environments where monitoring slight thermal variations is crucial.

The prowess of these sensors is showcased in controlled settings such as medical devices and climate control systems, where the accurate detection and regulation of temperature is essential for optimal operation.

Temperature probes are critical tools across various industries for their ability to provide precise and reliable temperature measurements.

From robust thermocouples used in high-temperature industrial settings to sensitive thermistors ideal for precise climate control, each probe type serves a unique purpose informed by its design and operational principle.

Whether it’s harnessing the thermoelectric effect in thermocouples or utilizing the predictable change in resistivity in RTDs, these instruments convey the sophistication of modern engineering.

Infrared probes further expand the toolkit with their non-contact approach to measuring temperature, ensuring safety and preventing contamination in sensitive environments.

Understanding how these probes work allows for the meticulous monitoring and control of thermal environments, which is indispensable in maintaining quality, efficiency, and safety in countless applications.

Contact Us

Take the next step in your exploration by diving into the nuances of temperature sensing technologies and the power of cloud computing. Contact us today to learn more about our wide range of IoT temperature sensors