September 2, 2022

CDC Digital Data Logger Requirements

According to the CDC, recent statistics reveal how many children have eight important vaccination doses by the age of 24 months. The highest percentages are among doses for MMR (Measles, Mumps, Rubella), Hepatitis B, and Chickenpox or Varicella, with over 90% of children 24 months and under who have it.

A digital data logger is pivotal in ensuring that vaccines are efficiently and safely given to humans. In fact, they play a more important role than you may realize.

Vaccines keep people healthy, and they save lives. It makes sense that the companies that manufacture such critical vaccines, the health professionals who distribute them, and the federal government regulate how to make and store them.

If you want to know more about what a digital data logger is and what the requirements are via the Centers for Disease Control and Prevention, you are in the right place. This article will give you thorough details regarding the regulations, starting now.

What Is a Digital Data Logger?

DDLs are electronic devices. They constantly record and monitor the parameters of an environment by using an external sensor probe.

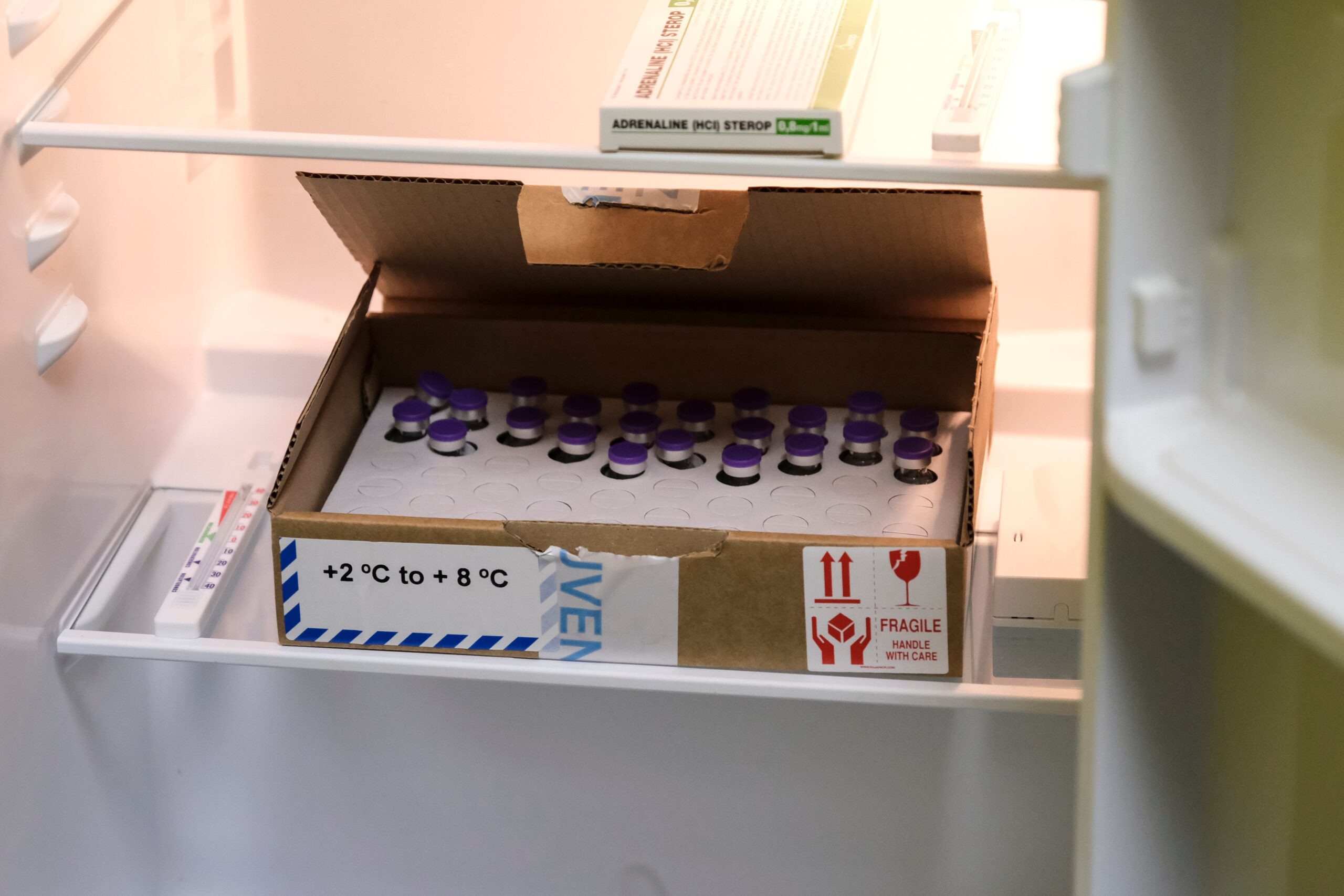

When digital data can have active storage, it can also have active analyzing, monitoring, and documenting. Most commonly, digital data loggers are used for vaccine monitoring in a refrigerator and freezers. Healthcare professionals must keep vaccines at a certain temperature, and digital data loggers help to accomplish this.

They ensure the quality of vaccines and their storage units.

TMD or Temperature Monitoring Device

The CDC says every vaccine storage unit needs a TMD for temperature control. Taking great care of every vaccine storage unit is a matter of life and death, so there must be an accurate log of the temperature history.

It costs far less to invest in a reliable device, like digital data loggers, than to dispose of bad vaccines. Out-of-range temperatures cause a loss of potency.

CDC Recommends Digital Data Logger or DDL

Digital data loggers give facilities that store vaccines the most accurate temperature information for the vaccine storage unit. It includes many details, like “temperature excursion.”

Temperature excursion refers to how long the vaccine storage unit has operated outside of the temperature range that is recommended. You cannot get these details from a simple thermometer that only tells you the minimum and maximum or the coldest and warmest temperatures the unit reached.

Digital data loggers go beyond this kind of detail, providing information regarding all temperatures on record for preset intervals.

Buffered Temperature Probe

Many digital data loggers use this because it is the most accurate method of measuring vaccine temperatures. In fact, a buffered temperature probe measures temperatures and matches the temperature of the vaccine closer than a standard thermometer. That is because a standard thermometer only matches air temperature.

Data You Can Download

Digital data loggers gather temperature data you can download on a computer. You would need a certain type of software, or you can retrieve it from a website. You, or the digital data logger coordinator, could set the frequency at which you want to read temperatures using the software or website.

To determine the viability of vaccines, reviewing the digital data logger detail is vital, so you will want to decide if a website program or independent software will work better for your facility.

Keep Data for Three Years

It is important to have a log of data to analyze. This means keeping data from digital data loggers for three years. This is so you can look back to see long-term trends or recurring problems.

State regulations may require that healthcare professionals keep the data for public vaccines longer than three years.

The CDC says to use digital data loggers, or another kind of appropriate TMD, for every vaccine storage unit you have and each emergency or non-emergency transport unit.

If the primary device in place breaks or malfunctions, the CDC says to have at least one TMD backup in place.

Features of Digital Data Loggers

The CDC guidelines state to have a few features with your digital data loggers, which include a detachable probe. This is how you can get the best reflection of the vaccine temperatures. For example, buffer the probe with sand, glass beads, glycol, or Teflon®.

DDLs must have an alarm that will sound for temperatures that are out of range. Likewise, they need a low battery indicator.

The temperature display must include the current temperature, besides the minimum and maximum. The recommendation for the “uncertainty” of the temperature is to be at +/-0.5° C (+/-1° F).

The user can program the reading rate or logging interval. You should record temperatures every 30 minutes at the least.

Certificate of Calibration Testing

Only use digital data loggers which possess a valid Certificate of Calibration Testing. Calibration testing ensures accuracy. It rates the digital data loggers’ readings and compares them to nationally accepted standards.

The Certificate of Calibration Testing should have the following details included:

- serial number

- model/device name or number

- recommended uncertainty [which is +/-0.5° C (+/-1° F) or less]

- date of calibration

- confirmation it passed testing

When you have the certificate, you want to know the right entity issues it. This is easy to do by verifying that the certificate has one or more of these items:

- conforms to ISO/IEC 17025 international standards of calibration testing and traceability

- performed in an accredited laboratory

- meets testing requirements and specifications for the ASTM Standard E2877 Tolerance Class F or higher

- has another accuracy validation method that is acceptable

- traceable per the NIST standards

Under the timeline given by the manufacturer, calibration testing must follow a set cadence. Preferably, complete testing every two to three years. Regular testing is a way to ensure accuracy.

Mishandling of Digital Data Loggers

Anytime a digital data logger hits against the vaccine storage unit, drops, or experiences damage in any shape or fashion, it is important to check its accuracy. You can do this by comparing it to a TMD that is properly calibrated and tested.

Additional Considerations

Digital data loggers are usually battery operated, so be sure to keep on hand an extra supply of batteries. Changing the batteries could affect the accuracy of the temperature. When you change the batteries, check it against a TMD that is calibrated and tested.

The manufacturer will provide more specific details regarding battery changes.

Some vaccines need ultra-cold storage. If so, you need a digital data logger specified for ultra-cold monitoring.

In the Event of a Temperature Excursion

If a staff member sees a temperature excursion or if a staff member hears an alarm warning of a temperature excursion, that staff member should notify the person in charge of the digital data logger right away. If they cannot immediately notify the person who coordinates the DDL, they should notify their supervisor instead.

All staff should know of a temperature excursion by placing a label that says “DO NOT USE” by the exposed vaccines. Those vaccines should be in a separate container, away from other viable vaccines. Do not discard them, though.

The coordinator of the digital data loggers or the supervisor must begin documentation. They will want to document the time and date of the temperature excursion.

Document the Temperature Excursion

Further, they will want to document the vaccine storage unit temperature. If the room temperature is available, they must document this too. Include the minimum and maximum temperatures, if available, from the time of the event.

Other items to include in the documentation are as follows:

- how long it could have affected the vaccine

- description of what happened

- inventory of affected vaccines

- other than vaccines, list other items in the vaccine storage unit, like water bottles

- before the event, problems with the storage unit

- any additional relevant details

You can contact the vaccine manufacturer(s) or immunization program for guidance beyond this. They can advise you whether you can use the affected vaccines or if patients will need a recall for revaccination.

Regular Maintenance

Vaccine storage units and associated equipment need regular maintenance to ensure they are functioning at their fullest efficiency. Cleaning coils, checking seals, and checking door hinges often is important practices for regular maintenance.

Manual-defrost freezers will need to be defrosted if the frost exceeds 1 cm. The manufacturer may have a distinct suggestion for the frost limit, and you will want to become familiar with that. Ensure that you place the vaccines in another unit temporarily that has the correct freezer temperature.

Cleanliness is vital, so you will want to ensure that there is no fungal or bacteria growth. This means cleaning the interior of every vaccine storage unit regularly. You do not want to risk a temperature excursion, so you must do this quickly.

You must have your backup service generators serviced consistently. At the very least, annually. Test them quarterly.

Vaccine Storage Unit Temperature Adjustments

Over time, you will find you may need to adjust the temperature of the storage unit. It could be because of the season, like winter or summer, or because of the room temperature.

Have the vaccine coordinator make the adjustments. It must be based on the digital data logger’s monitoring log. Also, make adjustments when the workday is slower. Avoid times when the vaccine storage unit door must frequently open and close.

Before making the adjustment, verify that the vaccine storage unit has a secure connection to a power source. Then, verify the storage unit’s temperature.

Wait 30 minutes. Do not open the door, allowing the stabilization of the temperature. After 30 minutes, check the temperature again to discover if you need to make a change.

If you find that an adjustment is necessary, first, refer to the owner’s manual. It will have detailed instructions.

When making a minor change, either colder or warmer, slowly turn the thermostat knob. Avoid going beyond the correct temperature range.

After you make the change, leave the door closed for 30 minutes. This is to allow the temperature to stabilize. Then, recheck the temperature.

Water Bottles

Placing water bottles can help keep stable temperatures when placed on the top shelf, on the floor of the storage unit, and in the door racks. Particularly, you can use these for a vaccine storage unit that must open and close frequently.

Repeated String of Alarm Alerts

When a digital data logger has an alarm that goes off repeatedly, wait to disconnect the alarm. First, determine what the cause is and why before you disconnect it.

Perform a few basic checks of the power supply, unit door, and thermostat settings. After you check these items and the alarm continues to go off, or the temperature is still not in the correct range, move the vaccines to a backup storage unit. Call a repair technician to come and check the equipment.

If the vaccine storage unit is not keeping the recommended range of temperatures, do not keep the vaccines there. If you cannot stabilize the temperature, or if the range falls too high or too low consistently, your supply of vaccines is at risk.

SensoScientific for Vaccine Monitoring

Founded in 2005, SensoScientific understands the rigorous standards that the CDC and similar organizations set to keep up quality and keep the public safe. If you want to know more about the requirements for a digital data logger, we can help with our history of excellence and expertise.

Let’s talk about how we can help you save lives! Contact us today.